Advanced Manufacturing

Disruptive Innovation from Design to Delivery

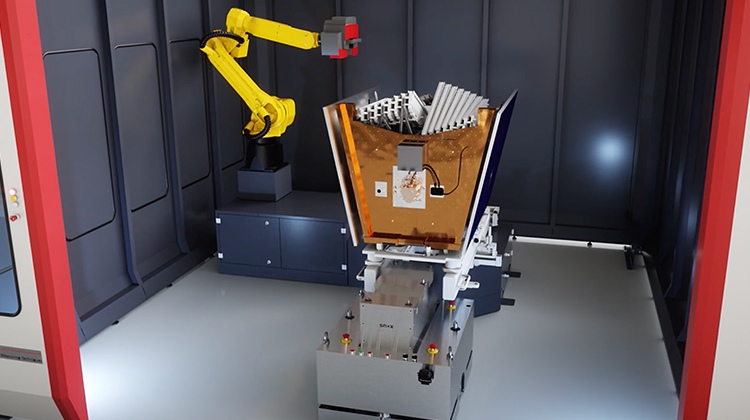

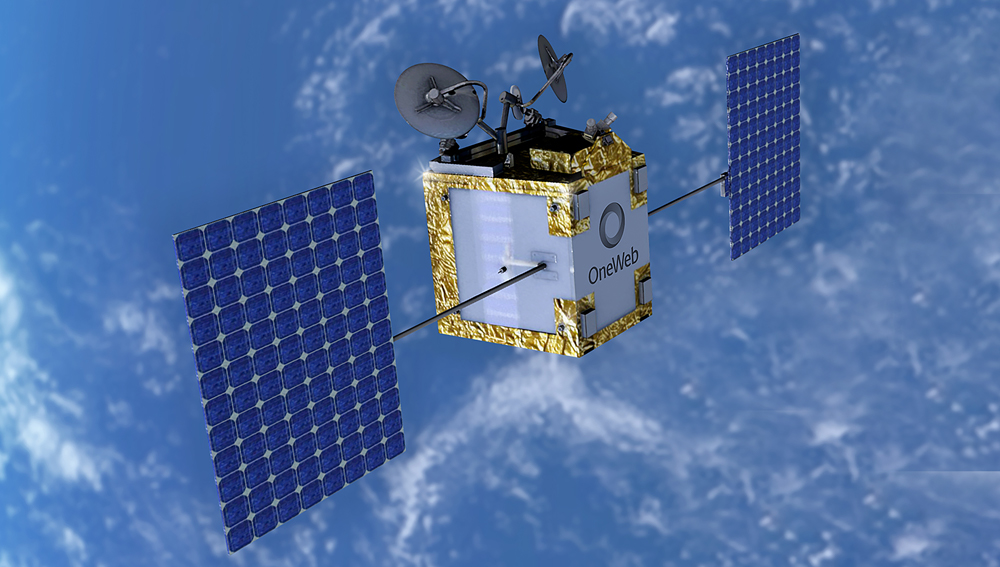

Our satellites and production lines are designed for mass manufacturing. Using our proven and tested production processes, we guarantee repeatability. We are a paperless factory, using digital twin technology, auto-transfer vehicles, geo-localization and smart tools with inspection cameras for end-to-end quality. Our robust testing ensures on orbit quality with unit level testing completed by each supplier. We perform functional testing at the module and satellite level with automated test setup and scripting.

Learn more about our capabilities at each of our sites:

Toulouse Facility

Created the unique satellite design and manufacturing technique

Florida Factory

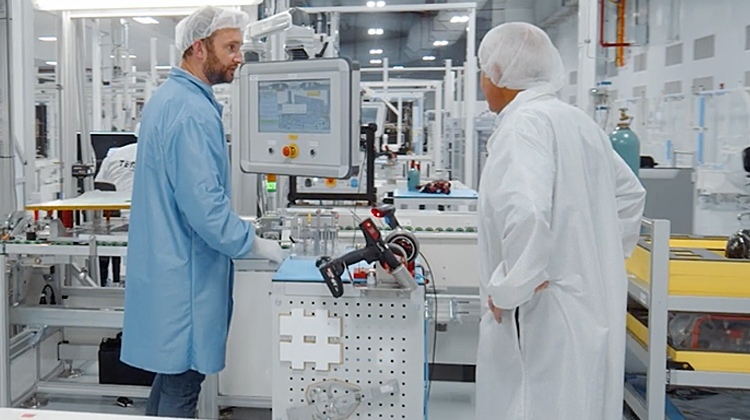

Opened in July 2019 and achieves a production rate of up to two satellites a day

Our manufacturing facility in Exploration Park in Merritt Island, Florida, USA. The 142,000 sq-ft facility has one of the most advanced production lines in the industry. The assembly line is made of four modules built in parallel and integrated with simple assembly.

Engineering is embedded in each of our stations, allowing technicians to produce quality spacecraft.

Our proven FAL assures quality and on time delivery.

Time Control Oriented

Quality Oriented

Lean Manufacturing Oriented